In recent years, the continuous development and upgrading of emulsification machines have formed a series of multiform and multi-purpose emulsification machines. Today, let’s talk about a popular emulsification machine – vacuum homogenization emulsification machine. Many people may be attracted by the word “vacuum”. Yes, the vacuum of emulsification machines originally has these functions.

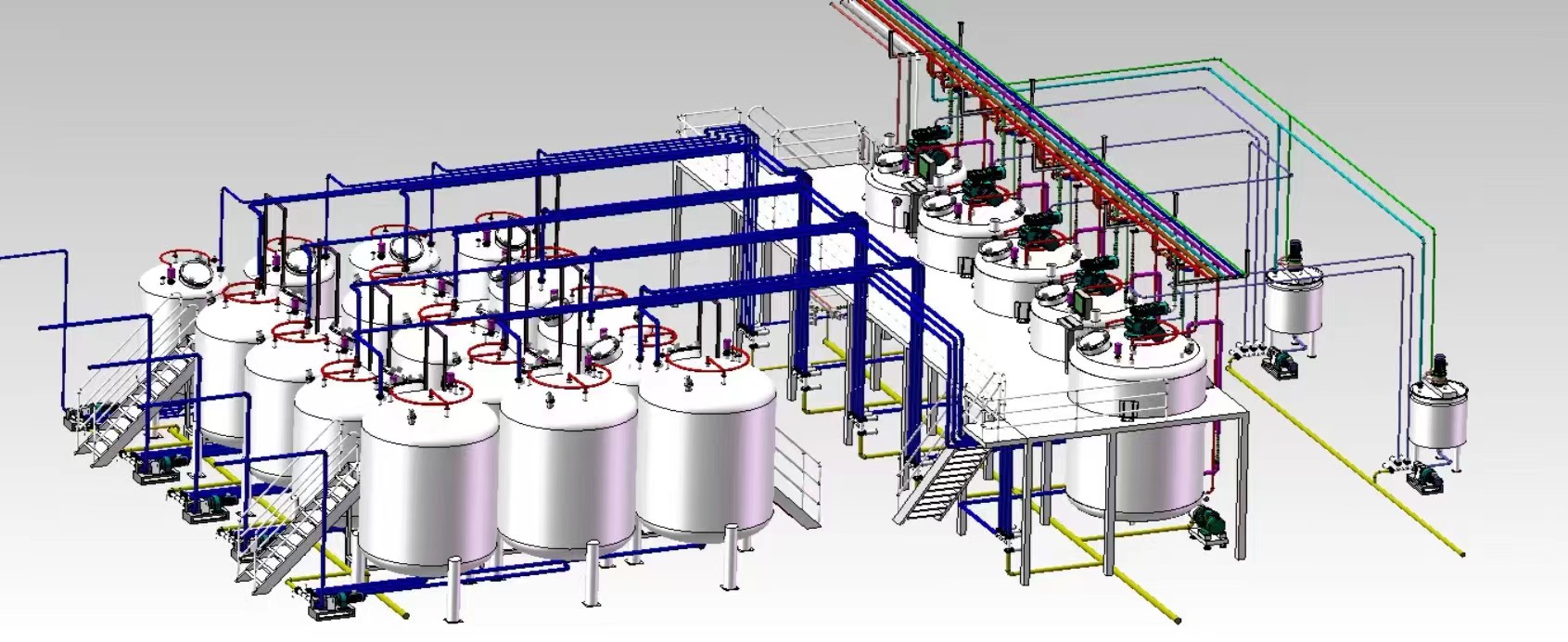

TopSail Vacuum Homogeneous Emulsifier

Function 1: Suction

The vacuum homogenization emulsification machine consists of three main pots, one water phase pot, one oil phase pot, and one homogenization main pot. The water phase pot and the oil phase pot are used to hold the two important raw materials for emulsification, water and oil. The main pot is used to homogenize and shear the two raw materials. Separating them is to ensure product quality and better control of emulsification products. So, how does the main pot absorb materials? By extracting the air from the main pot, a low-pressure vacuum is formed. When the valve connecting the water and oil phase pots is opened, the main pot will automatically absorb the raw materials from the auxiliary pot due to the pressure difference to maintain consistent air pressure inside the pot.

Function 2: Prevent foaming

When the raw materials are sheared, homogenized, and emulsified in the main pot, the vacuum environment inside the main pot should be maintained, and there should be no excess air. This is because if air enters during the mixing process, it is easy to enter the stirred product and form bubbles, which not only affects the homogenization process but also affects the quality of the product.

Function 3: Prevent product oxidation

Some raw materials are prone to oxidation when in contact with air during the production process, and the vacuum environment isolates oxygen, thus ensuring the effectiveness of the produced products.

The article is organized and edited by TopSail. TopSail is a daily chemical equipment supply brand that integrates design and development, equipment manufacturing, installation, maintenance, and upgrading. With 30 years of production experience, it has successfully provided high-quality solutions, emulsifying machines, production line equipment, and more for thousands of domestic and foreign daily chemical and cosmetics enterprises.

中文站

中文站 En

En